The Continuous Flight Auger (CFA) technique is one of the quietest piling solutions available and is virtually vibration-free, making it ideal for working in close proximity to existing buildings or in environmentally-sensitive areas.

Basic Technique

A hollow-stemmed continuous flight auger is rotated into the ground to the required depth, or degree of resistance. As the auger is withdrawn, concrete is pumped down the hollow stem at a specific flow rate and pressure to maintain the pile shaft from collapsing, or voids forming in the concrete, this process is crucial to the success of the pile and is monitored closely by the rig operator by the use of computerised instrumentation. After the auger is extracted and the pile concreted to the surface, a reinforcing cage is then inserted into the wet concrete by excavator or by using a cage-vibrator for longer cages.

Our fleet includes CFA rigs weighing between 25 and 155 tonnes which are capable of installing piles up to 35m deep, and with pile diameters ranging from 350mm to 1200mm. Quinn Piling have an experienced team of design engineers in-house who can work promptly and proficiently to overcome un-foreseen site conditions (as they arise) to mitigate potential delays. Further, we can review geo-technical information at any stage of the project and value-engineer the design to reduce costs or programme duration.

CFA Piles can be installed relatively quickly and economically without the need for casing, bentonite or polymers, in both cohesive material such as clay and and non-cohesive material such as sand, gravels and glacial tills.

CFA piles are suitable for both load-bearing piles and for contiguous or secant retaining walls.

Advantages

- Minimal disturbance, hence limited risk of damage to adjacent structures

- No casing is required

- Suitable for all soil types

- Ideal for retaining walls

- Speed of installation

Instrumentation

All Quinn Piling CFA rigs are fitted with the latest generation NDT piling rig computer systems – a fully-integrated interactive tool with touch-screen interface in the the rig cabin which enables our CFA rig operators to monitor and accurately control all aspects of the pile construction consistently and to specific quality-controlled specifications. As each pile is completed, the pile data is transmitted from the rig via a cell phone network to the ‘cloud’ for review on a net-connected device, thereby enabling real-time quality control. The system provides instant data on important parameters such as:

- Auger depth

- Auger rotations

- Penetration speed

- Rotary torque

- Crowd winch force

- Extraction force

- Extraction speed

- Concrete pressure

- Concrete flow

- Total concrete volume pumped

- Productivity

Cased CFA Piling

Cased CFA combines the benefits of a rotary and a CFA solution proving particularly beneficial and effective when installing larger contiguous and secant-piled retaining walls. The single flight auger allows much faster continuous drilling whilst the casing helps to keep the pile vertical, within tolerance and in the case of a secant piled wall, watertight. The rotary drive units for the casing and the augers are connected but rotate in opposite directions, simultaneously drilling them into the ground. As in a traditional CFA technique, the spoil travels up the auger string and is deposited from the top of the casing into a series of telescopic tubes safely expelling it directly into a disposal vehicle, a skip or to a holding area at ground level.

Concrete is then pumped through the hollow stem of the auger as it is retracted and the cages are installed once the pile is complete.

Our on-board software system is used to monitor and control pile construction in a similar manner to traditional CFA piling.

Piling Case Studies

See how we overcome complex ground challenges, deliver reliable solutions, and create lasting value for clients across a wide range of sectors.

PD Ports Teesport Berth 1: Phases 1 & 2

This project involved the reconstruction of 800m of the suspended […]

Read Case Study

Dublin Port Cross Berth Quay

The Roadbridge / L&M Keating Joint Venture (RBLMK JV) appointed […]

Read Case Study

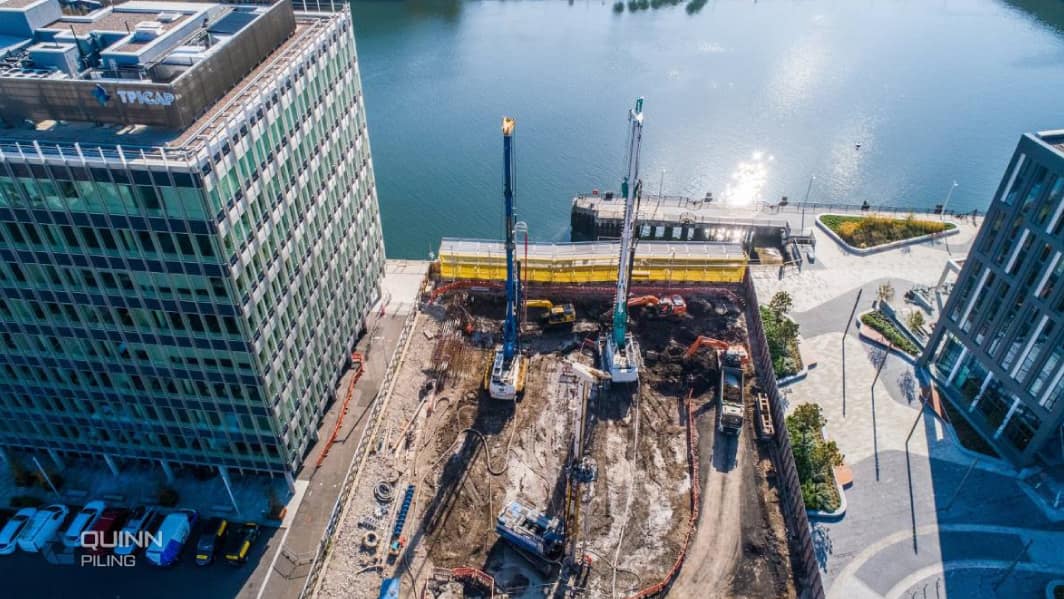

Belfast City Quays Three

Quinn Piling were awarded the contract to install the piling […]

Read Case Study