A mini-pile generally has a diameter of between 100 and 300mm and can extend to depths of over 50m.

Basic Technique

Quinn Piling have a fleet of mini-pile rigs ranging in size from 2.5 to 18 tons. This equipment is extremely versatile and the smaller rigs can operate within buildings. Piles may be vertical or raked and can also be pressure-grouted for increased capacity if required. Drilling techniques include cased, auger and rotary-percussive. Either a reinforced steel cage, steel circular hollow section or a centralised steel reinforcement bar may be used.

What is it used for?

- Construction of high-capacity small-diameter piles

- Installation of piles under existing structures such as bridges or even overhead power lines

- Underpinning or strengthening of existing structures both externally and/or internally

- Slope-stabilisation works

- Construction of propped or unpropped retaining walls

- To resist hydrostatic uplift pressures

- Upgrading existing floor slabs

Quinn Piling can offer high capacity mini piles with safe working loads of up to 1200kN.

Advantages

- Ability to bore through variable and difficult ground conditions e.g. masonry or existing concrete foundations

- Construction within restricted working areas and/or low headroom

- Working within existing premises with minimal disruption to other operations

- Low vibration

- Permanent liners can be incorporated into the solution for installations in very soft ground conditions.

Piling Case Studies

See how we overcome complex ground challenges, deliver reliable solutions, and create lasting value for clients across a wide range of sectors.

PD Ports Teesport Berth 1: Phases 1 & 2

This project involved the reconstruction of 800m of the suspended […]

Read Case Study

Dublin Port Cross Berth Quay

The Roadbridge / L&M Keating Joint Venture (RBLMK JV) appointed […]

Read Case Study

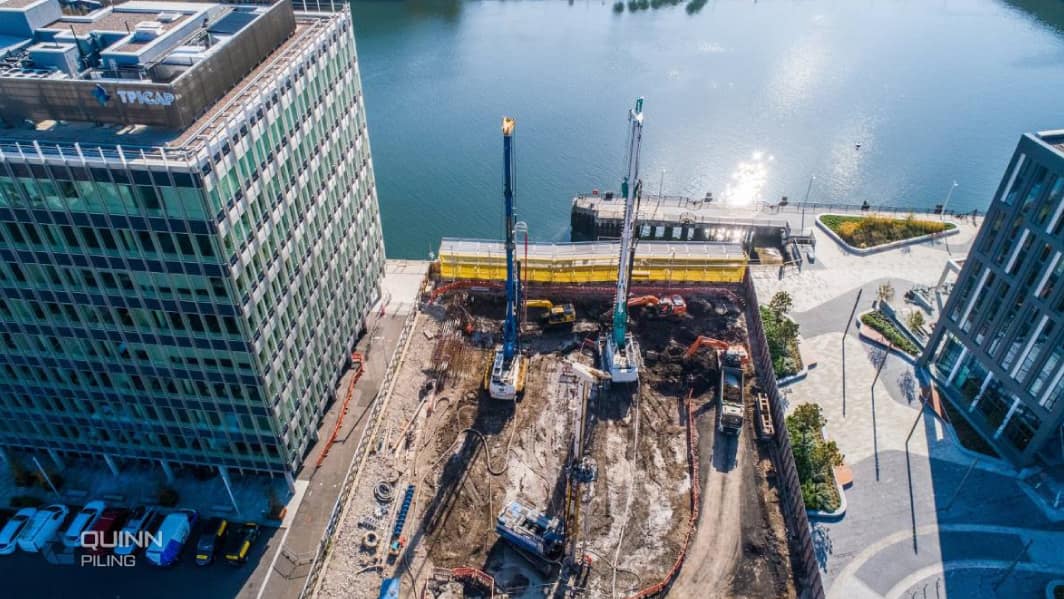

Belfast City Quays Three

Quinn Piling were awarded the contract to install the piling […]

Read Case Study