Drilled piles are commonly used on projects where underground obstructions are expected/encountered or if the designed pile is required to penetrate dense or rock strata to form a pile or rock socket. The type, diameter and depth of the pile will be influenced by the soil/rock type, the load or tension required and the constraints of the project on the piling method.

Basic Technique

The term Odex is an abbreviation for Overburden Drilling EXcentric. Odex piling is a drilling method suitable for boring through boulders and rock strata.

A specialist heavy duty drill ‘string’ is lowered into a steel tube or outer casing. Once drilling starts, the Odex drill bit quickly cuts ahead of the steel casing which enables a number of ‘wings’ on the bit to open out. The bit can now drill a hole with a diameter slightly greater than that of the steel casing. At the same time the ‘shoulder’ of the drill bit hits against a ‘shoe’ on the inside of the casing. This allows the steel casing to be hammered down simultaneously and closely behind the drill bit. High pressure air discharged through flushing holes in the face of the drill bit push the drill arisings back up the casing to be caught by a ‘shroud’ and discharged into a skip or other means of spoil collection.

Once the desired depth has been reached, the drill bit is turned once in reverse. The ‘wings’ fold back in allowing the drill to be withdrawn back up inside the casing – leaving the casing in place.

The pile is then filled with concrete or grout after a reinforcement cage or solid bar is placed.

The casing tube can either remain permanently or be removed after the concrete or grouting process has been completed.

Quinn Piling are the most experienced ODEX specialist in the UK and Ireland; coupled with an extensive range of equipment we are able to offer a distinct advantage over competitors at tender stage and help to reduce costs and duration of works.

Odex piling is used for

- Drilling through boulders / obstructions / rock strata

- Installing either temporary or permanent casing

- Drilling rock-sockets

- Pre-drilling for CFA projects

- Wide variety of sizes available

Piling Case Studies

See how we overcome complex ground challenges, deliver reliable solutions, and create lasting value for clients across a wide range of sectors.

PD Ports Teesport Berth 1: Phases 1 & 2

This project involved the reconstruction of 800m of the suspended […]

Read Case Study

Dublin Port Cross Berth Quay

The Roadbridge / L&M Keating Joint Venture (RBLMK JV) appointed […]

Read Case Study

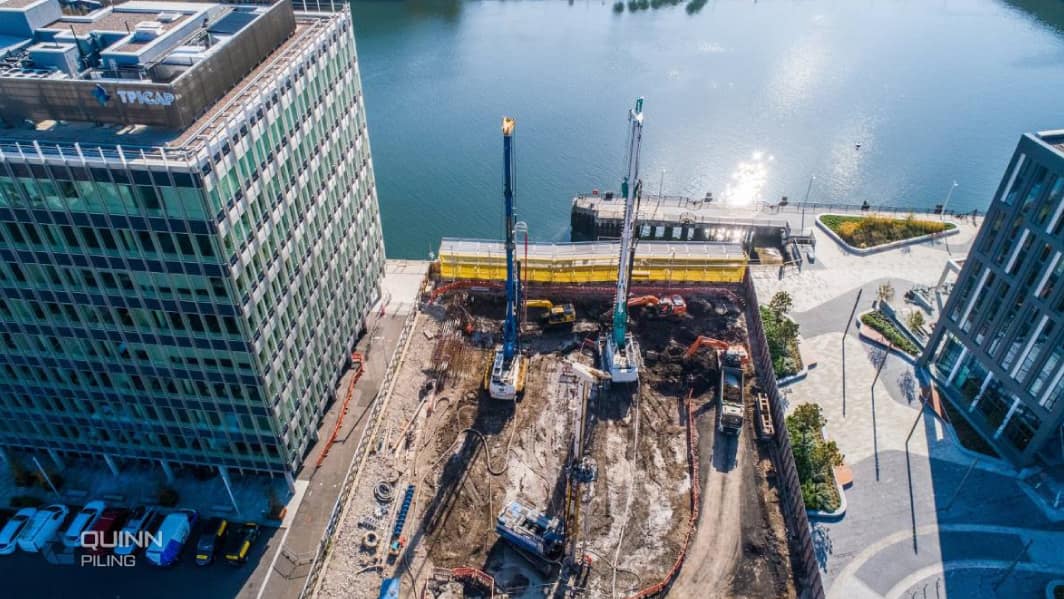

Belfast City Quays Three

Quinn Piling were awarded the contract to install the piling […]

Read Case Study