Rotary Bored Piles are usually employed for large commercial and industrial developments, public buildings, transport infrastructure and marine projects.

About

Bored piles are often larger diameter than conventional continuous flight auger (CFA) piles and are used to support greater loads, overcome underground obstructions, penetrate ground too hard to bore using a continuous flight auger or create piles with a cut-off level beneath the platform level. As the rotary bored technique enables the reinforcement to be added into the open bore rather than into the ready poured concrete, as in CFA, it has the distinct advantage of allowing the cage to be the full depth of the pile.

The standard method for construction is to screw a temporary outer steel casing / sleeve into the ground. At the same time, an auger /digging bucket or core-barrel is used to excavate and ‘muck-out’ inside the casing. When the pile toe level has been achieved, a reinforced steel cage is introduced into the bore, and concrete is poured by means of a ‘tremie-pipe’ to the required level. The temporary segmental steel casing can then be withdrawn by the rig or a casing oscillator and used at the next pile location.

In addition to the basic technique, Quinn Piling Ltd utilise specialist proven adaptations to suit more challenging ground conditions, site requirements or programmes, such as rock-socketing to achieve high capacity loads, the use of permanent casing or geotextile socks to prevent ‘wash-out’ and loss of concrete, the utilisation of drilling fluids such as bentonite and vinyl-polymer where the bore requires support during excavation, and also the employment of specialist air-driven ‘Down-The-Hole’ hammers (DTH) to get through harder rock types.

Our early involvement in projects has often resulted in significant savings in both programme and cost for many of our clients. Our success on these projects has led to a very high percentage of repeat business and an unrivalled reputation for quality, safety and value-engineered solutions.

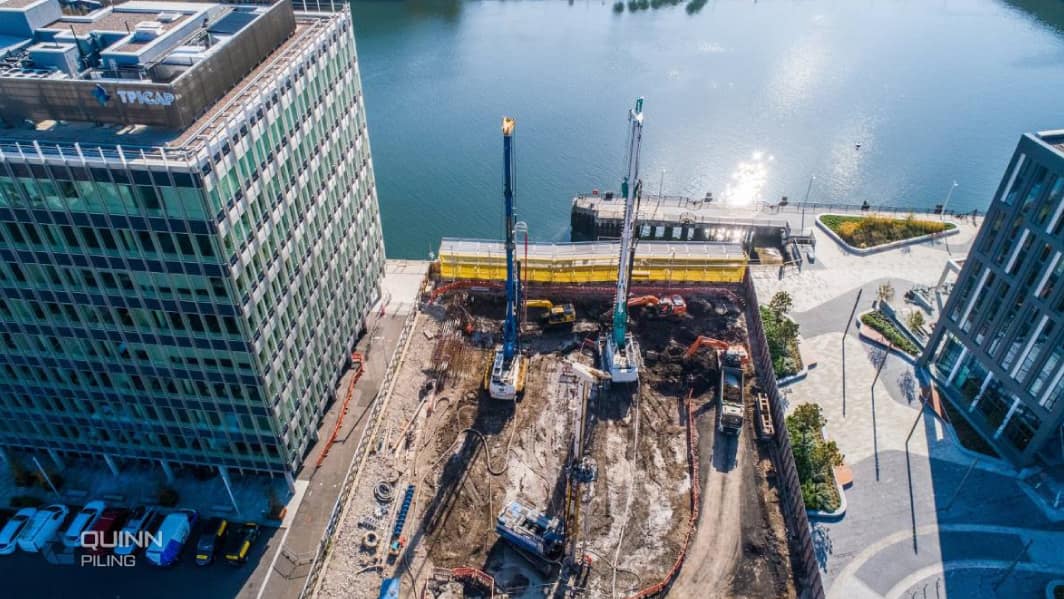

Quinn Piling has developed specialist expertise in delivering large, complex and technically challenging projects.

Advantages

- Accommodate large loads

- Greater depths possible up to 60m

- Suitable for all soil types

- Wide variety of sizes up to 3m in diameter

- High levels of accuracy

- Suitable for marine works

- Allows the use of complex pile testing instrumentation

- Better suited for the use of full-length reinforcement cages as the cage is placed into the bore before concreting

- RTB rigs are more powerful and capable of boring in challenging ground conditions

- RTB rigs have a wide range of augers, digging and coring tools which can be changed relatively quickly to overcome a wide variety of ground conditions and obstructions

Piling Case Studies

See how we overcome complex ground challenges, deliver reliable solutions, and create lasting value for clients across a wide range of sectors.

PD Ports Teesport Berth 1: Phases 1 & 2

This project involved the reconstruction of 800m of the suspended […]

Read Case Study

Dublin Port Cross Berth Quay

The Roadbridge / L&M Keating Joint Venture (RBLMK JV) appointed […]

Read Case Study

Belfast City Quays Three

Quinn Piling were awarded the contract to install the piling […]

Read Case Study